Plymouth Machine Integration, LLC

455 E. Cady Street, Northville, MI 48167

(734) 787-3977 | info@plymouthmachineintegration.com

PMI represents...

a resource you can utilize when the issues you are struggling with in your project are threatening your success. A wide range of direct experience in auto racing, high performance off-shore boat racing, and passenger car calibration can be applied to your project quickly and at low risk.

PMI has direct experience in a wide range of engineering activities:

- Camshaft profile design

- Mechanical component specification, design, and development

- Software specification, from clean sheet to championship winning result

- Issue identification and resolution

- Mechanical...Analysis of fatigue failures in metal parts. Real potential solutions will be proposed

- Electrical...Failure analysis

- Wiring loom design

- Calibration. Passenger car, auto racing (direct involvement in multiple Indy 500 wins), med duty truck, off-shore marine (championship results), pleasure craft marine (poker run boats and sport yachts), OBD-M

- Durability test specification and management

Please contact PMI to discuss how your project could benefit.

Capabilities

Acrobat Reader is needed to view this pdf file. If you do not have Acrobat Reader installed on your computer please click here to be redirected to the Adobe website for installation instructions.

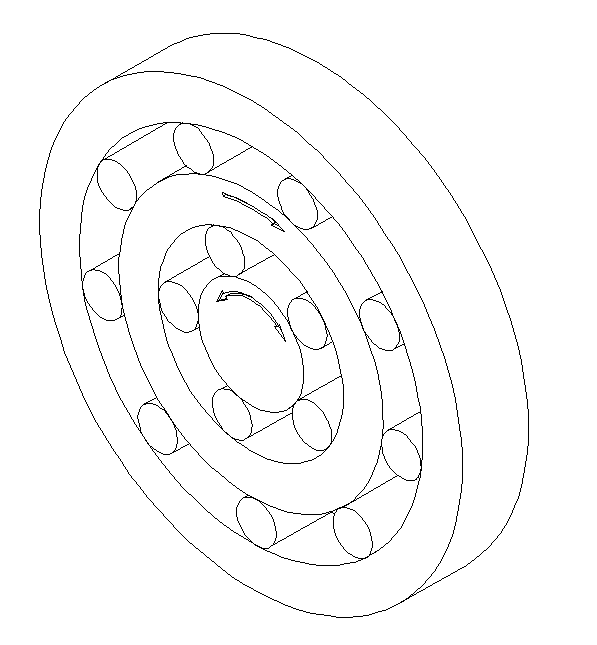

Mechanical Animation

PMI can turn your ideas into mechanical animations. These can illustrate interference issues, but also are valuable communication tools.

PMI Innovations

Re: Elimination of false brinelling in roller element bearings

False brinelling is a problem in assemblies which have low relative motion, high vibration, and a rolling element bearing. An example of this would be the bearings in the pitch control mechanism in wind turbines (Doll, G.), which may remain in a specific position for long periods of time.

The lubricant film is gradually displaced, allowing metal to metal contact. The vibration in the joint causes this contact to produce physical damage. Purposely inducing small amounts of relative motion can be helpful, but the benefit is limited since the lubricant can be pushed aside in either direction.

Plymouth Machine Integration has made a provisional patent application for a solution which uses two concentric one-way bearings, installed such that their actions are opposed. With a modest amount of oscillatory motion, large movements of the intermediate race, and therefore both sets of rollers, are produced, providing an even distribution of the lubricant. This motion in the intermediate race is the result of the oneway clutch in one of the two bearings holding that race motionless with respect to first the inner, then the outer race, depending on the direction of rotation within the period.

Note that this solution does not resolve issues from assemblies that lie motionless for substantial periods of time between uses (spare electric motors for example). Oscillatory motion of a magnitude large enough to engage the one-way clutch is required. This oscillatory motion can be either natural to the operation of the machine or superimposed on the control strategy.